3M 3762 QLM hot melt adhesive specially for polystyrene and packaging

- For heat-sensitive packaging materials

- Bonds expanded polystyrene

- Safe to use

- 5 kg carton

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

What are the characteristics of 3M 3762 QLM?

The 3M 3762 QLM is a Low Melt adhesive from the Scotch-Weld range manufactured by 3M.

In contrast to the 3M 3762 Q reference, which is applied at approximately 210°C, this adhesive is applied at a lower temperature of around 130°C.

This significant temperature reduction allows for adhesion on heat-sensitive surfaces, such as expanded polystyrene.

Applications

The formulation of 3M 3762 QLM provides great versatility, but it is primarily used in packaging applications (with heat-sensitive substrates) such as:

Bonding corrugated cardboard.

Creating displays.

Cushioning expanded polystyrene in cartons.

Product characteristics and customer benefits

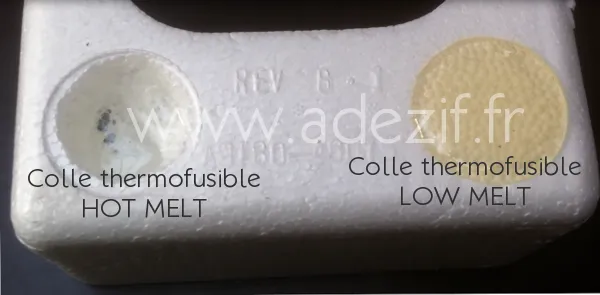

The photo below demonstrates that a low melt hot melt adhesive does not degrade polystyrene, unlike a high-temperature hot melt that can cause damage due to its higher application temperature.

Applying at approximately 130°C offers safety to the user, significantly reducing the risk of burns. Additionally, there are fewer odors and fumes released during application.

Compared to 3M 3792 QLM, this adhesive has a shorter open time of 25 seconds and a lower viscosity, resulting in a more liquid adhesive.

It can be easily applied using an electric hot glue gun. Two compatible references include the 3M TC/TC-Q Applicator and 3M TC/TC-Q LT Applicator.

It is crucial to use this product in well-ventilated areas to prevent the accumulation of fumes released by the molten adhesive. The safety data sheet is available at www.quickfds.com.

Technical data table

| Technical Information | 3M 3762 QLM |

|---|---|

| Color | Light amber |

| Packaging | 5 kg carton |

| Base | Thermoplastic resin |

| Open time | 25 seconds (for a semi-circular bead of 3 mm diameter, wood/wood) |

| Temperature resistance | Up to 55°C |

| Softening point | 96°C |