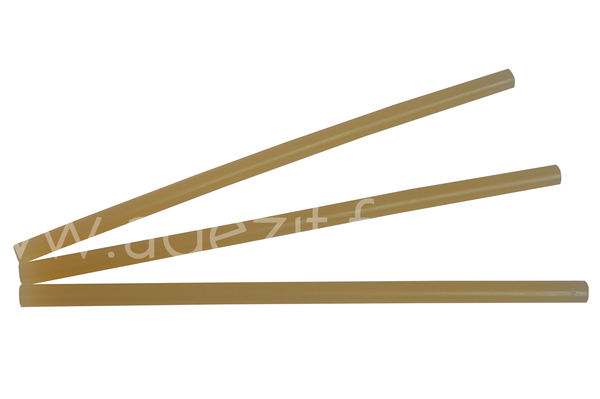

Hot melt adhesive sticks for electric glue gun

- Quick bonding and controlled flow

- Economical product

- Resistance to plasticizers

- Flexible and durable bonding

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

What is a hot melt adhesive stick?

Hot melt adhesive is a practical, simple, effective, and fast solution for permanently bonding two surfaces. It is a one-component adhesive based on thermoplastic resins. The most commonly used types are EVA (Ethylene Vinyl Acetate) and polyamides.

It is solvent-free, eliminating heavy investments for solvent recovery or incineration.

Hot melt adhesives are used regularly in industry in the form of sticks (standard in 12 mm, 11 mm and 13 mm in diameter) or granules, and are used to bond several materials (cardboard, wood, paper, cork, rubber, glass, metal, cloth, felt…). They are single-component glues, and Adezif offers several references with different fusion temperatures, different viscosities, different open times…

| Type of Component | Composition | Properties |

|---|---|---|

| Thermoplastic polymers (e.g., EVA) | 35 to 50% | Adhesion and cohesion |

| Tackifiers in resin form | 20 to 35% | Provides tack even when hot. Initial adhesion is almost immediate. |

| Plasticizers | 0 to 10% | Elasticity |

| Waxes | 5 to 25% | Viscosity when molten |

| Stabilizers | 0.1 to 0.5% | Prevents degradation of the glue when applied hot |

| Fillers | 0 to 5% | Increases viscosity |

| Others (such as colorants, etc.) | Color, etc. |

We sell two different types of hot melt glues :

HOT MELT glue – Fusion point of about 200° C : It enables fast application on most materials. It is without solvents and is economical.

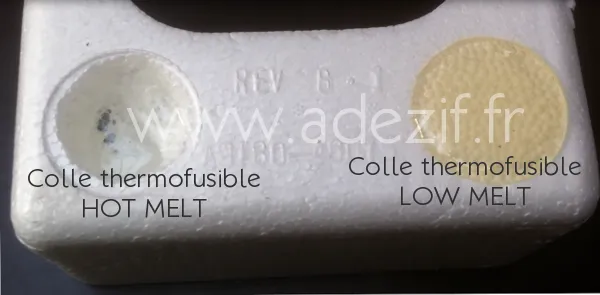

LOW MELT glue – Fusion point of about 130°C : Low melt glue has an important advantage: safety (can be interesting for protected workshops or prisons). It also allows you to glue materials that are sensitive to heat like some plastics (see photo above), or to accelerate production time with a shorter open time.

Hot melt adhesive is available in solid form in various formats:

Cannelé or non-cannelé sticks (standard diameters of 11 mm, 12 mm, and 13 mm): This is the most classic form, which we sell predominantly. 3M has designed notched sticks that allow for greater precision in glue application.

Granules: For this format, please feel free to consult us.

14 kg blocks for melters: Please request a quote for this type of reference.

When using stick form, it is applied through an electric hot glue gun: It becomes fluid when heated, is applied hot in liquid form, and develops performance and cohesion as it cools below its melting point.

It is recommended to apply it indoors and to avoid assembling large pieces due to the relatively short open time.

It can also be applied by simple bonding, meaning it only needs to be applied to one of the two surfaces, followed by assembly with slight pressure.

Some examples of industrial applications of hot melt glue

Packaging and conditioning industry

Bonding cardboard displays

Wood industry (such as pallet manufacturing) or furniture making

Printing and book manufacturing

Graphic arts / decoration

Electronics market

Footwear industry

...

Some tips for using hot melt glues with applicator

It is used to bond many non-porous materials as well as porous ones (such as cardboard, wood, paper, cork, rubber, glass, metals, fabric, felt, etc.).

It has the advantage of penetrating very well on all surfaces, with some formulations allowing adhesion to more difficult or heat-sensitive materials.

Adezif offers numerous references with varying melting temperatures, viscosities, and open times...

To glue expanded polystyrene, choose the 3M quad track glue gun with 3762 LM Low melt glue, at low melting point (avoids burns on the hot guns, reduces open time) or HM 267 low melt glue with a small viscosity.

If the flow is too high (up to 1.2Kg per hour), choose a glue gun nozzle with a smaller diameter (diameter 1.6mm or 1.8mm), which will allow you to be more precise.

It's better to draw a line of glue along the length rather than applying two large dots at both ends. This will increase the mechanical strength of the bond.

Advantages of hot melt adhesives

| Solid state at room temperature

Before use, the adhesive is available in a solid state, simplifying storage, handling, and transport. It can be stored at room temperature for an almost unlimited duration. |

| Immediate adhesion - very quick setting

Bonding strength is achieved as soon as the adhesive cools within a few seconds. Open time is typically a matter of seconds: the duration between applying the product and assembling the components. |

| Different application temperatures

Various formulations allow for variable application temperatures, enabling the bonding of different materials, including those sensitive to heat: |

| Use on various porous and non-porous materials

These adhesives can bond to a wide range of substrates, whether porous or non-porous. Some formulations allow adhesion to plastics, coated cardboard, polystyrene, etc. Possible bonding on cardboard, wood, paper, cork, rubber, glass, metals, fabric, felt, leather, etc., due to the high viscosity of the product that quickly penetrates the surface. |

| Ease of application

The stick is inserted into an electric heating gun, which allows for the application of the adhesive in a liquid state through a nozzle. Certain precautions must be taken to avoid burns, but the application itself is very easy. Different types of hot melt guns and nozzles are available. Simple bonding is all that is needed. |

| Solvent-free

Non-toxic, avoiding heavy investments for solvent recovery or incineration. |

| Productivity gain

No need to wait for the adhesive to dry before using the materials, resulting in time savings and increased productivity. It does not require extensive training for the workforce. |

Differences between hot melt and low melt adhesives

| Characteristics | Hot Melt Adhesives | Low Melt Adhesives |

|---|---|---|

| Melting Point | Approximately 200°C | Approximately 130°C |

| Application Speed | Allows for quick application on most materials | Extruded at much lower temperatures, providing a safer application |

| Solvent-Free | Yes, making them economical and environmentally friendly | Yes, with lower emissions of odors and fumes |

| Safety | Higher risk of burns due to high temperatures | Significantly reduces burn risk for operators, making them suitable for protected workshops or correctional facilities |

| Material Compatibility | Ideal for most materials without heat sensitivity | Suitable for heat-sensitive materials, such as expanded polystyrene |

| Production Efficiency | Allows for fast production times | Can accelerate production with shorter open times |

Visual Example

Left: hot melt adhesive melted the polystyrene

Right: low melt adhesive kept the polystyrene intact

The ADEZIF "HM" range of hot melt adhesives

Adezif offers a wide range of EVA (Ethylene-Vinyl Acetate) hot melt adhesives, which is the name of the polymer on which the product is based. EVA adhesives are mainly used in industry, crafts and DIY. Their versatility makes them suitable for a wide range of applications, including low-temperature use and bonding to difficult materials.

Advantages of Adezif EVA hot melt adhesives :

- Solvent-free

- Very good shelf life

- Good adhesion to many substrates

- Versatility, numerous application possibilities (variation of setting time and open time)

- Possibility of coloring

- Softening point between 70°C and 110°C: can be used with a traditional glue gun

- Economical solution

- Low sensitivity to humidity

Possible packaging :

- 20 kg carton of 12 mm diameter sticks and 200 or 295 mm length

- 43 mm diameter studs

- 20 kg bag of adhesive granules

Uses of Adezif EVA hot melt adhesives :

- Packaging: food processing, freezing

- Binding

- Woodworking

- Bonding on difficult materials, including plastics

- Bonding of various foams

- Gluing of artificial flowers

- Automotive industry: paintless dent removal

- Construction: baseboards, electrical ducts

- Luxury bottles

- Wax for administrative seals

- Wax for scrapbooking

- Gluing of fiber optic cables, fiber networks and wave guides

- ...

| Photo | Réf. | Applications | Colour | Shore A hardness | Application temperature | |

|---|---|---|---|---|---|---|

| HM210 | Paper, cardboard for the packaging industry, DIY. Quick closing of kraft cardboard, American boxes... | Cream beige | 93 | 160 - 200 °C | Quote |

| HM250 | Kraft cardboard, American crates, wood. Packaging industry, DIY. Cardboard stations... | Yellow | 66 | 180 - 200 °C | Quote |

| HM480 | Plastic, paintless dent removal (D.S.P.) heavy duty... | Yellow | 76 | 160 - 200 °C | Quote |

| HM482 | Plastic, paintless dent removal (D.S.P.) medium run... | Yellow | 80 | 160 - 200 °C | Quote |

| HM484 | Wood, packaging, plastics, varnish, ceramics, non-woven, DIY... | Yellow | 76 | 160 - 200 °C | Quote |

| HM620 | Manual work, gluing of wood, glass, paper and heat sensitive surfaces: foams, expanded polystyrene, laminated surfaces, thermoplastic films... | Translucent | 87 | 120 - 150 °C | Quote |

| HM624 | Packing, DIY, difficult gluing, wiring, skirting, wood, flowers... | Translucent | 80 | 150 - 210 °C | Quote |

| HM800 | Universal multi-support glue. G.S.B., florist, packaging, DIY, hobbies, fiber gluing, optics... | Translucent | 78 | 160 - 205 °C | Quote |

| HM204 | Difficult bonding, plastic, metal, preheated metals, wood, ceramic, varnish... | Pale yellow | 87 | 170 - 190 °C | Quote |

| HM408 | Difficult bonding, packaging, DIY, seals, plastics, PP, cables, skirting boards... | Translucent | 76 | 160 - 200 °C | Quote |

| HM960 | Gluing and difficult materials. Glass, cold metals, plastics (PE, PP), wood, cardboard, paper. Gluing of difficult to glue cardboard (laminated cardboard), freezer packaging... | Translucent | 60 | 160 - 200 °C | Quote |

Non-exhaustive list. Contact us for advice on the most appropriate hot melt adhesive for your application.