Slit liner for handling adhesive dots with gloves

- Glove-friendly handling

- Time-saving on production lines

- Less waste, higher quality

- Customized adaptability

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Easily handle your adhesives with a slit liner

The liner, also known as the release liner, is a backing material that preserves the adhesive layer until application.

It also facilitates the handling and placement of adhesive tapes or die-cut adhesive parts. It is removed just before applying the adhesive to the final surface.

In industrial environments, peeling off die-cut adhesive dots from their liner can be a real challenge for operators.

Several factors make this task more difficult:

Adhesive dots are often hard to grasp, especially when they are thin, flexible, or small in size.

Using fingernails to lift them is time-consuming and can damage the die-cut adhesive piece.

Operators frequently wear gloves, making handling even more difficult—or even impossible.

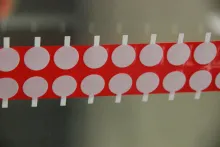

When you order custom die-cut adhesive formats from Adezif, we deliver your product on a liner that can be slit based on the shape and layout of your adhesive pieces.

In the video above, the liner is slit along its length, creating a longitudinal pre-cut that makes removal easier.

"Backslit liner" technology

In the adhesive tape industry, the process of making a partial pre-cut on the liner's back is called backslitting. This operation divides the release liner into two or more sections, making it easier to handle and apply die-cut adhesives in industrial environments.

Benefits of slit liners for gloved operators

Choose efficiency and comfort for your industrial operators:

✅ Improved handling – A progressive release liner removal partially exposes the adhesive piece, ensuring easy grasping without damage.

✅ Reduced waste – Prevents damage to custom die-cut adhesives caused by delicate or excessive handling.

✅ Time-saving – Faster and more efficient application process on production lines.

✅ Optimized ergonomics – Minimizes unnecessary movements and enhances operator comfort, even with gloves.

Our expertise in custom adhesive solutions ensures precise adaptation to your specific needs, offering tailored slitting and liner processing solutions for your production environment.

📩 Contact us today for personalized support and to find the best liner slitting solution for your applications.