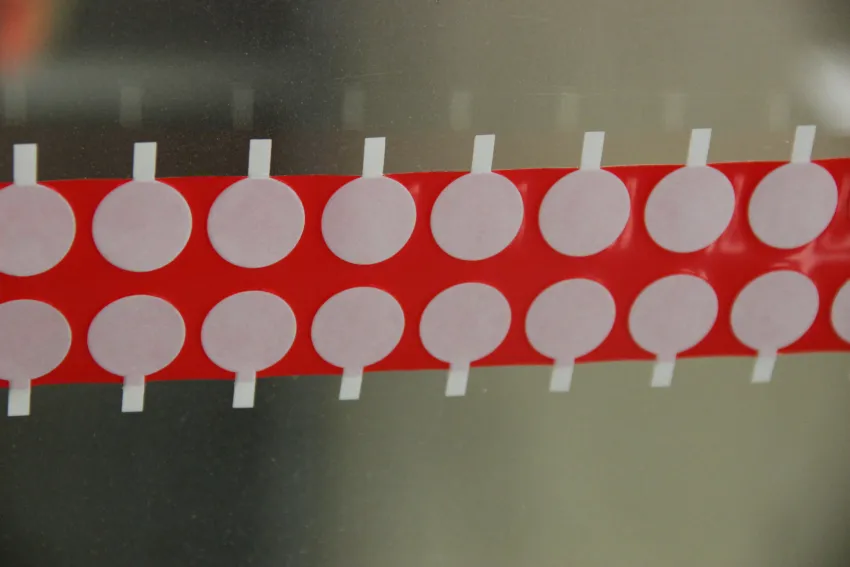

Die-cut adhesive pieces

- Your adhesive already die-cut in your dimensions

- Several pieces available

- Fast custom manufacturing

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Your custom die-cut adhesive

The company ADEZIF has a considerable fleet of special cutting machines spread over its 3 workshops :

ADEZIF NORD (located in Lomme 59)

ADEZIF NORMANDIE(located in le Havre 76)

ADEZIF PARIS (located in Hérouville-en-Vexin 95).

This fleet of machines allows us to offer a wide variety of pieces. It is also possible to produce new cutting tools very quickly. Die-cutting technical adhesives to the exact measurements required for an application enables you to save a considerable amount of time during your adhesive application operations. There are several die-cutting presentation possibilities that adapt to users’ industrial and logistical constraints.

From very small production batches (around 10 pieces) to large batch production (several million pieces), ADEZIF has die-cutting technology that meets manufacturers’ needs. Almost all adhesive tape references can be cut on our machines.

There are several die-cutting techniques for adhesive pieces :

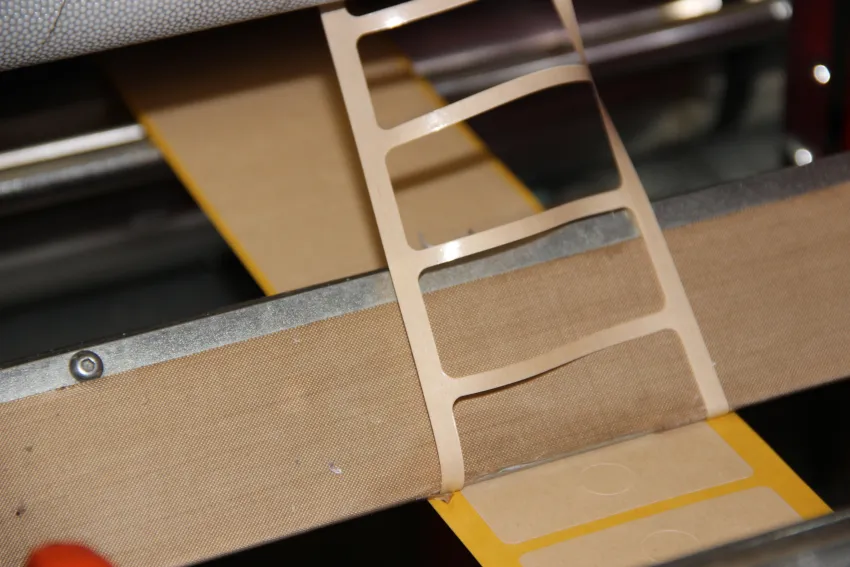

Flat bed die-cutting

Small and medium batch production

Limited tooling cost

Here is a demonstration video about flat bed die-cutting a double-sided foam adhesive tape :

Rotary die-cutting

Medium and large batch production

Variable tooling costs (from a few hundred to several million €uros)

Here is a demonstration video about rotary die-cutting a double sided VHB adhesive tape.

Digital die-cutting

Small and medium batch production

No tooling cost

Different technology (oscillating blade, rotary blade, water jet cutting)

These different custom cuts are available on the sites of Adezif Nord, Adezif Paris and Adezif Cartha.

How to choose your custom die-cut adhesives ?

Consult the different presentation possibilities of die-cut pieces for easy and optimal use.

For a custom product, it is possible to laminate different products together prior to die-cutting. We can, for example, laminate double-sided foam adhesive to a repositionable adhesive.

Industrial applications for die-cut adhesives

Double-sided pads for making POS

Transparent single sided pads for closing brochures and boxes

Bonding front panels/screens in the electronic industry

etc.