Different adhesive masses used in single and double-sided tapes

- 3 families: rubber, acrylic, silicone

- Adhesive specifications

- Choose the right adhesive mass

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

The structure and characteristics of the three families of adhesive masses

Here are the three main families of adhesive masses along with their characteristics:

Rubber

The manufacturing of a rubber adhesive requires mixing natural or synthetic rubbers with various components to create adhesion. The chemical structure of the components is not modified; they are simply combined to produce the adhesive.

The rubber adhesive has the significant advantage of being very versatile at a low cost. Its initial adhesion (also known as tack) is excellent, but it generally exhibits medium resistance to aging, UV exposure, and temperature extremes. Natural or synthetic rubber adhesives are recommended for bonding non-polar surfaces and multi-use applications.

Acrylic

For the manufacturing of an acrylic adhesive, components are formulated to achieve specific chemical structures tailored for the desired adhesion. These undergo a chemical modification during processing, which can be adjusted according to the final adhesion performance needed.

This adhesive is notable for being transparent and is thus widely used for bonding transparent materials. Its initial adhesion is moderate but increases progressively over time. It exhibits excellent resistance to UV light, aging, shear forces, and solvents. Acrylic adhesives are recommended for permanent outdoor applications. The vast majority of technical adhesives on the market contain an acrylic adhesive mass.

Silicone

The manufacturing of a silicone adhesive involves mixing soft silicone rubber with brittle silicone resin and then curing it to produce the adhesive. By modulating the amounts of rubber, resin, and curing time, different types of silicone adhesives can be obtained with optimized performance.

Its initial adhesion is moderate, but this adhesive mass exhibits excellent resistance to high and low temperatures, UV light, and solvents. However, it is the most expensive of the three adhesive masses.

Each of these three adhesive masses can also have thermosetting properties: in this case, they require a polymerization cycle (time and temperature indicated in the product technical data sheets) to significantly enhance adhesive power and solvent resistance.

Summary Table of Adhesive Masses

| Rubber Adhesive | Acrylic Adhesive | Silicone Adhesive |

|---|---|---|

| Great versatility and low cost | Moderate initial adhesion | Generally low initial adhesion |

| High tack and initial adhesion | High final adhesion | Excellent adhesion on silicone materials |

| Limited durability | High resistance to UV, solvents, humidity | Excellent resistance to extreme temperatures (-60°C to +315°C) |

| Average resistance to extreme temperatures | Temperature use between -40°C and 150°C | Low resistance to hydrocarbons and plasticizers |

| Indoor application | Outdoor application | High cost |

| High aging resistance | Excellent aging resistance |

Criteria for choosing the right adhesive mass

The selection of the adhesive mass is based on several criteria, including temperature resistance, duration of exposure to usage temperatures, aging resistance, initial adhesion, substrate type, usage conditions, and, of course, cost.

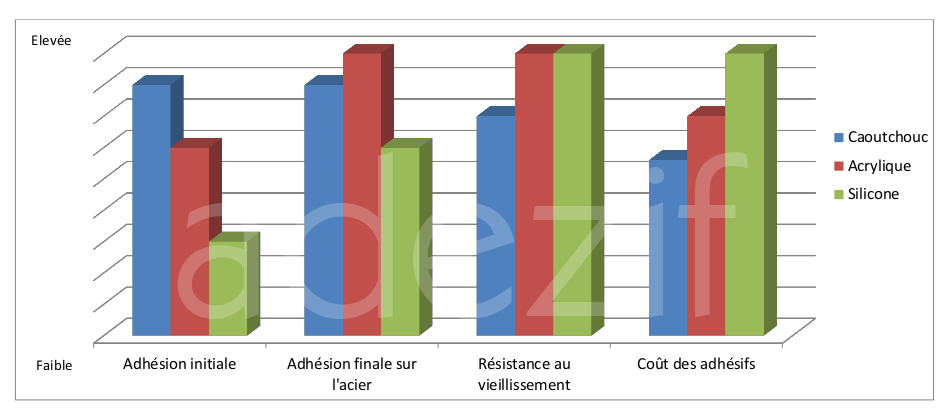

Here are comparative diagrams that provide an overview of the properties of each adhesive mass and can help in selecting the right adhesive:

Duration

The usage duration of an adhesive tape is a crucial criterion for adhesive selection. The importance of initial adhesion and final adhesion varies depending on whether the adhesive application is permanent or temporary. It is important to note that initial adhesion (or tack) and final adhesion are two different characteristics. A tape may have a medium tack but significant final resistance after 72 hours.

Temperature

The temperature exposure of the adhesive tape and the duration of exposure are also essential criteria. For very high temperature applications (above 160°C) or very low temperatures, only a silicone adhesive can provide the desired resistance.

Contact of the adhesive with the surface

A good bond requires perfect contact between the adhesive and the surface being bonded, known as wetting. To achieve good wetting of the surface, the surface tension of the substrate must be lower than that of the applied adhesive. The substrate should be smooth, dry, and free from contaminants (achieved through good surface preparation, which is essential before any bonding), and firm pressure should be applied to enhance contact between the adhesive and the substrate.

Usage conditions

Ambient conditions should guide your choice of adhesive: extreme temperatures, UV radiation, water, oils, solvents, etc.

Our team is available to assist you in choosing the adhesive that best fits your final application. Don't hesitate to contact us!