3M 5421 and 3M 5423 abrasion-resistant polyethylene anti-stick adhesive

- Excellent abrasion and wear resistance

- Low friction coefficient for easy sliding

- Reduces noise, squeaks and vibrations

- Width up to 609 mm, custom cut available

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Description of 3M 5421

3M 5421 is a single-sided adhesive tape with a high-density polyethylene (HDPE) backing, also known as UHMW (Ultra High Molecular Weight) polyethylene, manufactured by 3M.

Its rubber adhesive ensures immediate bonding on most surfaces, offering long-lasting adhesion.

Ultra High Molecular Weight polyethylene is a thermoplastic that combines high resistance to wear and abrasion, exceptional hardness to resist puncture and impacts, and low surface energy to significantly enhance sliding. It also serves as an effective solution for noise and squeak dampening.

This product is widely used for its non-stick properties and surface protection against wear, which extends the lifespan of industrial equipment. Additionally, its neutral and inert backing makes it suitable for food industry applications.

The 3M 5421 is thinner (170 µm), providing better conformability, while the 3M 5423 is thicker (280 µm), ideal for heavier-duty applications.

Applications

Industrial applications

Flat guide rails for conveyors or round guide rails

Friction rails for material handling

Glass bottle conveyor (reducing friction and noise between moving bottles)

Coal chutes, food chutes, grain chutes, foundry waste chutes, and abrasive waste chutes

Packaging tables

Vibratory bowls for part distribution or calibration

Non-stick coatings for spray or paint booths

Widely used in packaging and printing industries

Cone folding: applied on cone edges to facilitate product sliding

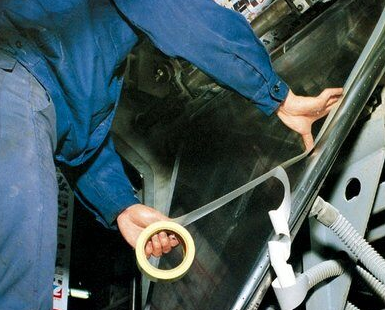

Automotive assembly

Solves noise issues caused by vibrations and friction inside vehicles.

Construction

Applied to joists to prevent floor creaks.

In roller blinds, 3M 5423 can be applied inside the blind case to facilitate smooth operation and reduce wear from friction.

Other uses

Facilitates drawer sliding.

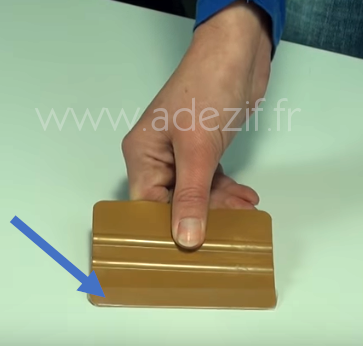

Applied to mechanical scrapers or manual squeegees, enhancing wear resistance and improving gliding properties.

Product characteristics and customer benefits

Key features of this non-stick, ultra-durable product include:

Wear and abrasion resistance → reduces replacement frequency of damaged parts. More durable than Teflon, though with a slightly higher friction coefficient compared to PTFE (like 3M 5490 or 5491).

Impact and puncture resistance → extends equipment lifespan and ensures effective surface protection.

Energy absorption → reduces unwanted noise.

Neutral PE backing → safe for use in sensitive environments, including food applications.

Low friction coefficient → enhances sliding and improves production speed, reducing noise like squeaks and rattles.

Non-stick surface → minimizes dirt accumulation, requires little maintenance, and is easy to clean.

Self-lubricating → maintains non-stick performance even after wear.

Chemical resistance → withstands exposure to inks, paints, and other chemical solutions.

Liner included → facilitates cutting to desired widths or shapes.

Rubber adhesive → ensures excellent initial adhesion for instant bonding.

Technical data

| Technical Information | 3M 5421 |

|---|---|

| Color | 5421: Transparent, 5423: Cream |

| Thickness | 5421: 170 µm, 5423: 280 µm |

| Length | 16.50 meters |

| Backing Material | Polyethylene with silicone paper liner |

| Adhesive Type | Rubber |

| Temperature Resistance | -35°C to 107°C |

| Adhesion to Steel | 280 cN/cm for 5421 and 5423 |

| Tensile Strength | 5421: 5.3 daN/cm, 5423: 9.6 daN/cm |

| Elongation | 5421: 300%, 5423: 500% |

| Transformation | Roll or format cutting |

| Available Widths | Up to 609.6 mm |