Surface protection with adhesive film

- Essential for a durable adhesive bonding

- Cleaning of surfaces before assembly

- Different steps for a successful preparation

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Applications of surface protection adhesive films

Surface protection is a varied and common application for avoiding shocks and scratches on products so that they will not get damaged. The adhesive tape is usually sold in a large width and is most frequently referred to as surface protection adhesive film.

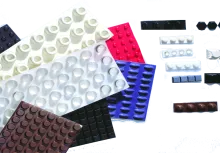

Surface protection tapes can be split into two main categories :

1. Temporary surface protection

The most common application is the temporary protection of a product from the manufacturing and processing of the product to its implementation or delivery. The purpose of the film is to protect the surface against potential shocks, scratches, dust, dirt or other damage.

The film range is quite varied and can be defined by 4 main characteristics :

The type of material : Depending on the material to be protected (Polyethylene, Polypropylene, Polyester, Co-extruded PE, Special UV film)

The thickness of the material : from 30 µm m to more than 200 µm

Adhesion strength : between 0.5 and 1.2 N/cm for an optimal bonding and easy removal

Colour of film : white, clear, green, blue, red custom printed...

Depending on your application, the rolls can be applied manually (roll of 33 to 100 metres) or by machine (500 to 2,000 metres long).

2. Definitive surface protection

The second application is final surface protection. There are many adhesive solutions for that :

UHWMPE tape (can withstand laser cutting)

Key markets

- Protection of metals : Protection during laser cutting, UV protection of painted metals

- Electronic : protection of screens...

- Plastic : Protection of PVC profiles for window manufacturing...

- Construction : Protection of aluminium profiles...

- Automobile : Car protection during transport, optical protection...

Some surface protection references available

Temporary surface protection. Ideal for smooth surfaces, especially glass. Leaves no trace after removal.

Temporary surface protection during manufacturing process. Ideal on metal profiles and plastics (PVC...). Preserves coatings from dirt and scratches

Temporary surface protection against dust, scratches or dirt. Ideal on grained plastics in the automotive industry. Suitable for many substrates

Ideal for repairing PE sheets on greenhouses or cultivation tunnels. Excellent UV and weather resistance. Economical.

Low coefficient of friction for a "slippery" effect. Very high resistance to abrasion and wear. Used for chutes and conveyors.

High resistance to abrasion and wear. Dampens noise and promotes sliding due its low friction coefficient. High chemical resistance.

High tensile strength. Combines strong adhesion and streak-free removal. Ideal for strapping, protecting and holding components and surfaces.

Adhesive film for permanent surface protection. Protects against light outdoor impacts. Versatile and ideal for construction and public works industry.

Protects smooth and shiny surfaces against scratches and light impacts. Holds in place without adhesive or glue. Compatible with large format printing.

Long-term protection against external aggressions in the automotive industry. Good resistance over time to cracking and bleaching. Resistant to UV rays.

Temporary surface protection. Suitable for both indoor and outdoor use. UV resistant for 6 weeks, clean removal within 4 weeks.

Transparent film against scratches, gravel, corrosion, and wear. Used on bikes, mountain bikes, cars, work surfaces to protect. High UV resistance, no yellowing.

Epaisseur importante de 1.14 mm. Idéal pour la protection de surface en sablage et grenaillage. S’enlève facilement sans transfert d’adhésif.