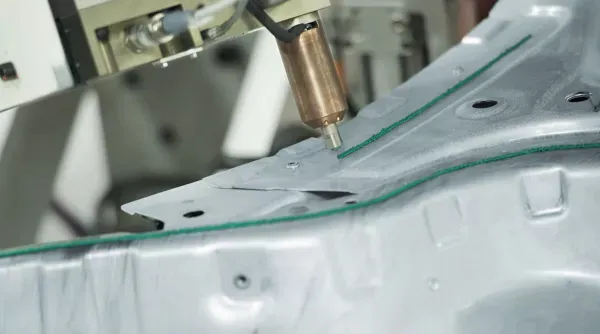

Body panel replacement with adhesive bonding

- Weld-free repair

- Long-lasting durability

- Corrosion protection

- OEM-approved products

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Why choose adhesive bonding for body panel replacement?

Replacing a body panel often comes with challenges: complex welding, risk of heat deformation, extended repair time, and potential corrosion issues after installation.

Today, a proven solution is widely adopted by body shops and certified repair centers:

👉 Body panel bonding with industrial adhesives and high-performance tapes.

Faster, cleaner, and safer, this method is now recommended by manufacturers, ensuring strong, invisible repairs while preserving the integrity of modern vehicles.

| 🚨 Problem | ✅ Adhesive bonding solution |

|---|---|

| Metal deformation risk | Cold assembly, no heat, perfect finish |

| Corrosion protection issues | Preserves all protective coatings |

| Long repair time | Fast application, instant fixation with tapes or quick curing adhesives |

| Challenges with aluminum or composite panels | Specialized adhesives for multi-material bonding |

| Vibration and water infiltration risks | Uniform stress distribution, reinforced sealing |

Where is adhesive bonding used in auto repairs?

✅ Bonded rear quarter panel replacement (on modern vehicles)

✅ Side panel bonding on steel or aluminum bodies

✅ Rocker panel replacement

✅ Roof panel attachment

✅ Composite panel assembly on electric vehicles

✅ Partial repairs on aluminum frames or damaged areas

💡 Did you know?

More and more automakers require bonding technology for specific repairs, especially on aluminum and hybrid panels.

FAQ about body panel bonding

🧽 1. How to ensure perfect adhesion on aluminum or composite panels?

Aluminum and composites have low surface energy, making them difficult to bond. Before applying adhesive, it is crucial to clean the surface with a degreaser and use a primer if necessary. Never touch the surface after preparation.

Surface cleaning/degreasing: ADEZIF AN500, 3M VHB Surface Cleaner

Adhesion primer: 3M Adhesion Promoter 111 (aluminum) or Sika Primer-207 (composites)

Recommended adhesives:

3M Panel Bonding Adhesive (OEM-approved epoxy)

SikaPower-4720 (structural epoxy)

🌡️ 2. How to prevent cracks caused by material expansion?

Different materials (steel, aluminum, composites) expand at different rates with temperature changes. A flexible adhesive absorbs these differences, preventing stress cracks. Avoid rigid adhesives for materials prone to expansion.

Flexible adhesives for thermal movement absorption:

Bostik 70-03A (two-part polyurethane)

Damping tapes for secondary parts:

🏎️ 3. How to ensure durability against vibrations and shocks?

A body panel undergoes constant mechanical stress (door slamming, road impacts). A high-strength structural adhesive absorbs vibrations and ensures long-term stability. Uniform pressure during application guarantees a solid bond with no weak points.

High-strength epoxy adhesives:

3M Panel Bonding Adhesive

SikaPower-4720

⏳ 4. How to speed up repairs and optimize workshop productivity?

Drying time is critical in auto repairs. To speed up work, use fast-curing adhesives or double-sided tapes for temporary positioning during polymerization. Always check open times and recommended curing temperatures.

Fast-curing adhesives:

Loctite 4090 (hybrid fast-bonding adhesive)

SikaPower-4720 (quick setting under pressure)

Instant temporary fixations:

🛡️ 5. How to prevent galvanic corrosion in steel-to-aluminum bonding?

Steel and aluminum create a galvanic reaction when in contact, leading to accelerated corrosion. Using a non-conductive adhesive and applying an anti-corrosion primer before bonding prevents this issue. Always ensure clean surfaces before application.

Non-conductive insulating adhesives:

3M Panel Bonding Adhesive

Anti-corrosion protection before bonding:

SikaCor Primer

🎨 6. How to ensure strong adhesion on a pre-painted or primed panel?

Painted or primed surfaces may reduce adhesion. Before applying adhesive, lightly sand the surface to create mechanical anchoring and clean with a degreaser. Always check the adhesive’s compatibility with the existing coating.

Recommended cleaning/degreasing: 3M VHB Surface Cleaner

Adhesives compatible with primers and paints: Sikaflex-527 AT, SikaFast-3000 Series

Body panel bonding method

| Step | Description | Recommended products |

|---|---|---|

1. Surface preparation

|

| 3M VHB Surface Cleaner (degreaser)

3M Scotch-Brite (abrasion)

SikaCor Primer (anti-corrosion) |

2. Adhesive application

|

| 3M Panel Bonding Adhesive (structural epoxy)

SikaPower-4720 (fast-curing epoxy)

3M Duopack Applicator |

3. Panel positioning and pressure

|

| Pneumatic applicator for consistent adhesive flow

Body panel clamps |

4. Finishing and corrosion protection

|

| 3M Scotch-Brite Roloc (finishing) SikaCor Primer (final protection) |

Adhesives and tapes for body panel bonding

| Product | Type | Primary use | Key benefits | |

|---|---|---|---|---|

| 3M Panel Bonding Adhesive | Epoxy (2-part) | Structural bonding of steel and aluminum panels | OEM-approved, high shear strength, corrosion-resistant | Quote |

| SikaPower-4720 | Epoxy (2-part) | High-strength panel bonding | Quick curing, impact-resistant, durable bond | Quote |

| SikaForce-7722 | Polyurethane (2-part) | Rigid panel bonding | Thixotropic, multiple curing speeds | Quote |

| SikaForce Powerflex Series | Polyurethane (2-part) | Elastic structural bonding | High-strength with flexibility for thermal expansion | Quote |

| Sikaflex-552 AT | Polyurethane (1-part) | Bonding aluminum and composite panels | Absorbs expansion, vibration-resistant, no primer needed | Quote |

| Bostik 70-03A | Polyurethane (2-part) | Bonding steel and composite panels | Flexible, absorbs vibrations and thermal movement | Quote |

| Sikaflex-265 | Polyurethane (1-part) | Exterior glazing and panel bonding | UV-resistant, weatherproof | Quote |

| Sikaflex-200 Series | Polyurethane (1-part) | General bonding and sealing | Long-lasting elasticity, multipurpose | Quote |

| Sikaflex-500 Series | STP Polymer | Interior/exterior bonding without primer | Solvent-free, high initial tack, durable | Quote |

| SikaFast-3000 Series | MMA (methyl methacrylate) | Rivet and mechanical fastener replacement | Fast setting, flexible, low odor | Quote |

| SikaFast-5200 Series | Acrylic (2-part) | Elastic structural bonding | Low odor, minimal surface preparation | Quote |

| Korapur 125 | Polyurethane (1-part) | Structural panel bonding and sealing | High elasticity, resistant to vibrations and weather | Quote |

| Korapop Alu | MS Polymer (1-part) | Multi-material bonding, aluminum fixation | Flexible, resistant to expansion, solvent-free | Quote |

| Double-sided acrylic adhesive tape | Bonding composites and low surface energy plastics | Flexible, no primer needed, resistant to extreme conditions | Quote |

Each case is unique. Our technical experts are available to help you select the right adhesive or tape for your repair needs.

📞 Contact us now for a quote or expert recommendation.