Single sided adhesive tape

Packaging

Printed adhesive tape

Filament adhesive tape for industry

Polypropylene adhesive packing tape

Removable assembly

VELCRO industrial adhesive

Dual Lock adhesive tape 3M

Magnetic adhesive tape

Surface protection

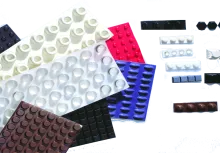

Self-adhesive bumper

Polyurethane adhesive tape

Polyethylene adhesive tape for surface protection or greenhouse repair

Non-slip adhesive tape

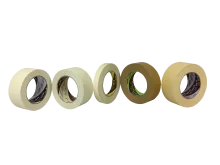

Paper masking adhesive tape

Single sided cloth adhesive tape

Plastic-coated PVC adhesive tape

Lead adhesive tape

High temperature

Single sided aluminium tape

Single-sided polyester adhesive tape

Glass cloth adhesive tape

Kapton adhesive and insulating polyimide tape

PTFE teflon adhesive tape

Characteristics of a single-sided adhesive tape

A single-sided adhesive tape is coated with adhesive on only one side. It consists of:

Two fixed elements: the backing and the adhesive layer.

Three optional elements: the varnish, the adhesion promoter, and the liner.

The varnish

The varnish (also called release) is applied to the non-adhesive side of the backing (the reverse side).

It helps to:

Facilitate the unwinding of the tape, preventing the backing from breaking while maintaining control.

Prevent adhesive transfer onto the backing.

Most backings have a varnish layer.

The backing

The backing is a thin, flexible material that can be coated with adhesive. Various types include: paper, metallic materials (aluminum, copper, lead, etc.), polyester, cloth, polyethylene, polypropylene, plasticized PVC, PTFE, Kapton, fiberglass, polyurethane, non-slip, magnetic, and removable materials like Velcro and Dual Lock.

Several characteristics are important when choosing a backing:

Tear resistance

Stretchability

Resistance when a tear has begun (such as a notch on the edge)

Impact resistance

Abrasion resistance

Water vapor impermeability

Printability

Dielectric resistance

The adhesion promoter

The adhesion promoter or priming layer is a pre-treatment that helps the adhesive bond to the backing, especially on non-stick surfaces (e.g., PE, PTFE).

This ensures good compatibility between the backing and adhesive for reliable and long-lasting adhesion.

The adhesive layer

For more details on the adhesives used in single-sided tapes, you can check our page dedicated to adhesive layers, outlining their characteristics and specifications.

Three main types of adhesive layers are distinguished:

Rubber

Rubber adhesives are highly versatile and cost-effective. Their initial adhesion (also called tack) is excellent, but they generally have medium resistance to aging, UV, and temperature.

Natural or synthetic rubber adhesives are recommended for bonding on non-polar surfaces and multi-purpose uses.

Acrylic

This adhesive is typically transparent, making it ideal for applications requiring the assembly of transparent materials. Its initial adhesion is average but improves over time. It has excellent resistance to UV, aging, shear, and solvents.

Acrylic adhesives are recommended for permanent and outdoor applications. Most technical adhesives on the market have an acrylic adhesive layer.

Silicone

Silicone adhesives have medium initial adhesion but offer excellent resistance to high and low temperatures, UV, and solvents. They are also used for bonding on non-stick surfaces.

Silicone adhesives are generally the most expensive of the three adhesive types.

The liner

The liner is very rare in the case of a single-sided adhesive tape. It is found in certain references of aluminum tapes to allow for easier and cleaner cutting without damaging the backing.

It can vary in thickness for automated removal or not.