Splicing application - Adhesive tape for flying splice

- Fast and strong splicing of moving reels

- Stationery, cardboard, printing, packaging

- Reduced machine downtime

- Range of recyclable repulpable adhesives

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

What Is Flying Splice For Reels?

Flying splice (also known as splice-on-the-fly or roll splicing) is a crucial technique in industries to change reels (paper, plastic film, or fabric) without interrupting workflows.

It involves joining an expiring reel with a new one at full speed using an adhesive tape that ensures a strong and reliable connection.

The main advantage of this technique is the elimination of machine downtime, boosting productivity and reducing idle time. It is indispensable for high-speed processes.

Common Applications:

Production of coated and uncoated paper

Printing (newspapers, packaging)

Manufacturing corrugated cardboard

Packaging (plastic films, bagging machines)

This method is primarily used in the paper industry, where productivity is critical. Flying splice ensures production continuity and often involves repulpable adhesives designed for specific splicing needs.

Adhesive Usage In The Paper Industry

Flying splice

Static splice

Patch repairs

Adhesive detection

Reel initiation

Reel closure

A Demanding Process

During a flying splice, the connection between two reels must be made quickly, often at speeds exceeding 300 m/min. Industrial adhesives ensure:

Instant adhesion

Shear resistance suited to mechanical tension

Durability under extreme temperatures (high or low), such as those encountered during calendering

Flying Splice Methods

Traditional Flying Splice:

Splicing reels at the entrance of a calender or coater.

Joint formed using a V or W shape.

Use of double-sided tapes with break tabs.

Suitable for moderate speeds and standard materials.

High-Speed Flying Splice:

Splicing reels at the entrance of a calender or coater at high speed.

Straight joint using splittable double-sided tapes designed for high-speed production.

Easy and quick setup, reducing operator training time.

Minimizes waste and errors in joint preparation.

Adhesive Tapes Adapted To Flying Splice

Key Criteria For Choosing Adhesive Tape:

- Substrates:

- Compatibility with materials (paper, cardboard, plastic films, etc.)

- Smooth, rough, coated, or uncoated surfaces

- Production Speed:

- Suitable for high-speed production (> 600 m/min)

- Instant adhesion to prevent detachment

- Mechanical Resistance:

- Shear and tensile strength

- Dimensional stability to prevent deformation

- Thermal And Environmental Conditions:

- Resistance to heat (up to 200 °C), UV, and humidity

- Type Of Splice:

- Permanent: Strong, durable adhesion

- Temporary or repulpable: Recycling compliance or splittable adhesive

- Adhesive Structure:

- Backing (non-woven, polypropylene, or unsupported)

- Optimized thickness to avoid bulking

- Ease Of Use:

- Smooth application, precise placement, and invisible splice if needed

- Standards And Requirements:

- Compliance with recycling standards (e.g., INGEDE)

- No adhesive migration, essential for plastic films or sensitive papers

- Cost And Productivity:

- Cost optimization and reduced production downtime

Criteria For Choosing Adhesives For Paper Reels

| Criteria | Details |

|---|---|

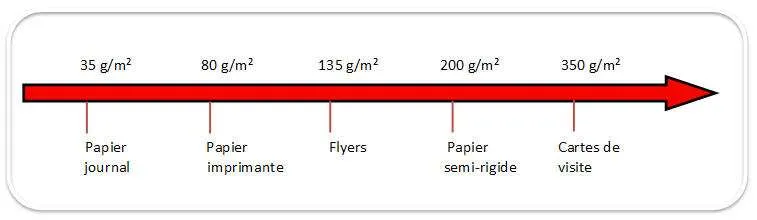

| Paper Grammage | Weight in grams per square meter (g/m²) to determine the tape's compatibility. |

| Paper Quality | Surface condition (smooth, rough, coated, or uncoated). |

| Rotation Speed | Reel speed in rotations per minute (RPM). |

| Temperature | Process temperature during manufacturing or calendering. |

Types Of Adhesive Tapes

| Type | Characteristics | Applications |

|---|---|---|

| Single-sided reinforced | High tensile strength, temporary hold | Heavy or tensioned reels |

| Double-sided adhesive | Fast, invisible splice for internal layers | Smooth, uniform surfaces |

| Repositionable adhesive | Adjustable before final bonding | Reduces costly errors |

| Repulpable hydro-dispersible | Recyclable, thin profile | Paper industry, recycling |

Examples Of Adhesive References

| Adhesive Type | Reference | Main Applications | Key Features |

|---|---|---|---|

| Single-sided | 4444 | Reel repairs and initiation | High mechanical resistance, thin paper compatibility |

| 51408 | Permanent splicing for newspaper printing | Deinkable, recycling-compliant | |

| Technical double-sided | 9004 | Temporary splice in demanding environments | High shear resistance, suitable for high speeds |

| ADEZIF NT239 | Flying splice for paper, cardboard, and films | Strong adhesion, non-woven backing, heat-resistant up to 200 °C | |

| ADEZIF NT340 | High-speed flying splice | Splittable, non-woven backing, high shear resistance | |

| 9576 | Splicing during stoppages and flying splices | Transparent polypropylene backing, UV and heat resistant up to 609.6 m/min | |

| Double-sided repulpable | EasySplice 51780 | High-speed splicing for printing and paper | Instant adhesion, hydro-dispersible, INGEDE-compliant |

| R9411 | Splicing coated and uncoated paper | Thin adhesive, high thermal resistance, recycling-friendly | |

| 6361 | Flying splice for lightweight papers and cartons | Splittable, no adhesive migration | |

| Q2 Splice 8531 | High-speed splicing for heavyweight papers | Splittable backing, high performance for fast processes | |

| 3110 | Flying splice with magnetic detection | Splittable adhesive, compatible with coated and uncoated papers, high precision for fast machines | |

| 906 | High-speed reel splicing | High initial adhesion, thin profile to avoid bulking, heat-resistant up to 200 °C |

Focus On Repulpable And Hydro-Dispersible Adhesive Tapes

Hydro-dispersible adhesive tapes, designed for paper reel splicing, enable efficient flying splice while meeting growing recycling demands.

They are water-soluble, leaving no residue or obstruction in industrial equipment.

Repulpable adhesive tapes dissolve entirely in the pulper per TAPPI UM213, leaving no residue and integrating seamlessly into recycling processes.

Key Features:

- Thin adhesive profile for smooth transitions

- High adhesion strength for all paper types

- Very high tack for quick restarts

- Exceptional shear resistance for splicing

- Heat resistance up to 200 °C

- 100% repulpable per TAPPI UM213 standards

INGEDE Certification For Recycling :

Certain repulpable adhesives, such as those from the TESA EasySplice range, are certified by INGEDE (International Association of the Deinking Industry).

This certification ensures that these adhesives facilitate the deinking process, which is essential during paper recycling. The process efficiently removes ink, enabling the production of high-quality recycled paper.

Key Benefits Of INGEDE-Certified Adhesives:

- Eco-friendly: Supports sustainable recycling practices

- High performance: Enables clean deinking without residue

- Compliance: Meets stringent industry standards for recycling

The goal is to support the circular economy by minimizing waste and enhancing the recyclability of paper materials.

Did You Know?

The TAPPI UM213 standard, established by the Technical Association of the Pulp and Paper Industry, defines testing methods to evaluate material repulpability during the paper recycling process.

Practical Tips For Optimal Flying Splice

Use wide adhesive tapes for high-speed splicing to ensure strong bonding.

Apply adhesive with a spatula to prevent air bubbles.

Leave a 2 mm margin at the reel edge to avoid adhesive creep.

Synchronize speed between the old and new reels.

Tilt the tape by 5° for a secure flying splice.