Electrical insulation of EV batteries with adhesive tapes

- High dielectric strength

- Short-circuit protection

- UL94 V0 insulating materials

- Lightweight and high-performance solutions

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

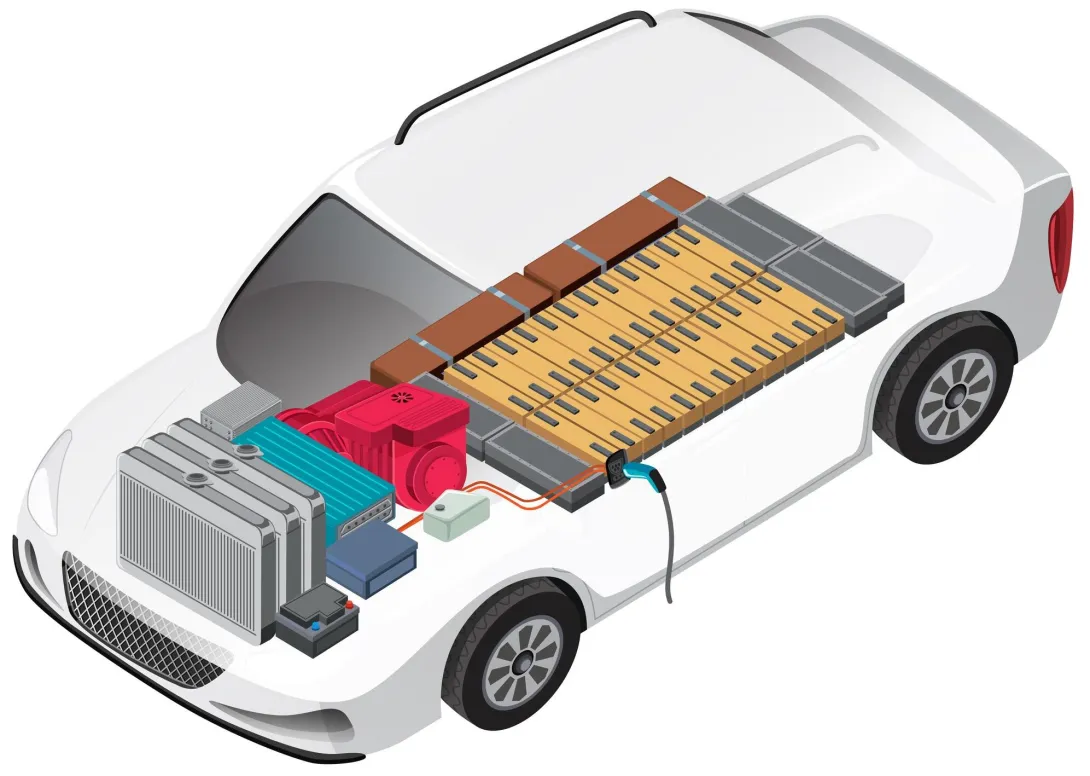

The Importance of Electrical Insulation for EV Batteries

Lithium-ion batteries are the heart of electric vehicles 🚗⚡.

However, without proper electrical insulation, they can become unstable and pose risks:

Risk of short circuits between cells

Overheating that can lead to thermal runaway

Premature wear of internal components

Effective technical solutions exist to protect batteries and extend their lifespan:

Ultra-resistant insulating adhesive tapes

Vibration-absorbing foams that protect cells

High-performance polymer films

These materials provide reliable electrical insulation in a lightweight form and are already adopted by leading battery manufacturers.

Our Solutions for Effective Electrical Insulation

How to effectively protect an electric battery? Insulation is not just a simple coating. It needs to be applied at multiple levels:

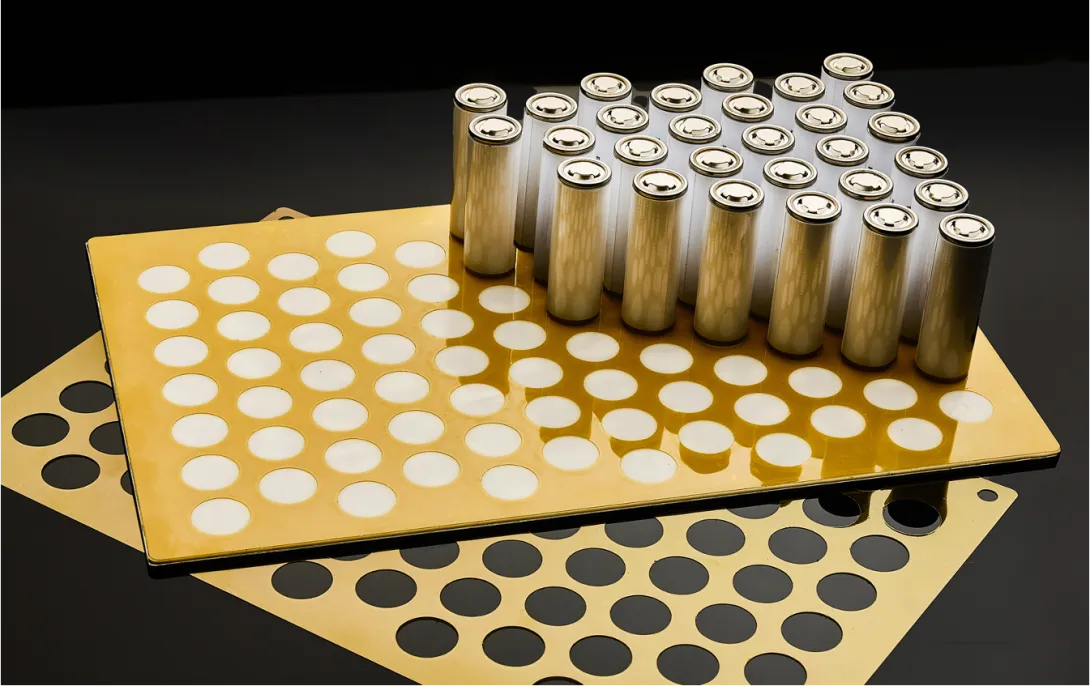

1️⃣ Battery Cell Insulation

Each cell must be individually insulated to prevent any internal short circuits and ensure safe operation.

High-temperature polyimide tapes ➝ Protect electrodes from stray discharges.

High-voltage insulating films ➝ Limit electrical interference.

Vibration-absorbing foams ➝ Reduce mechanical wear of cells.

📌 Example: A UL94 V0 polyimide tape placed around the cells prevents any unwanted contact between conductive components.

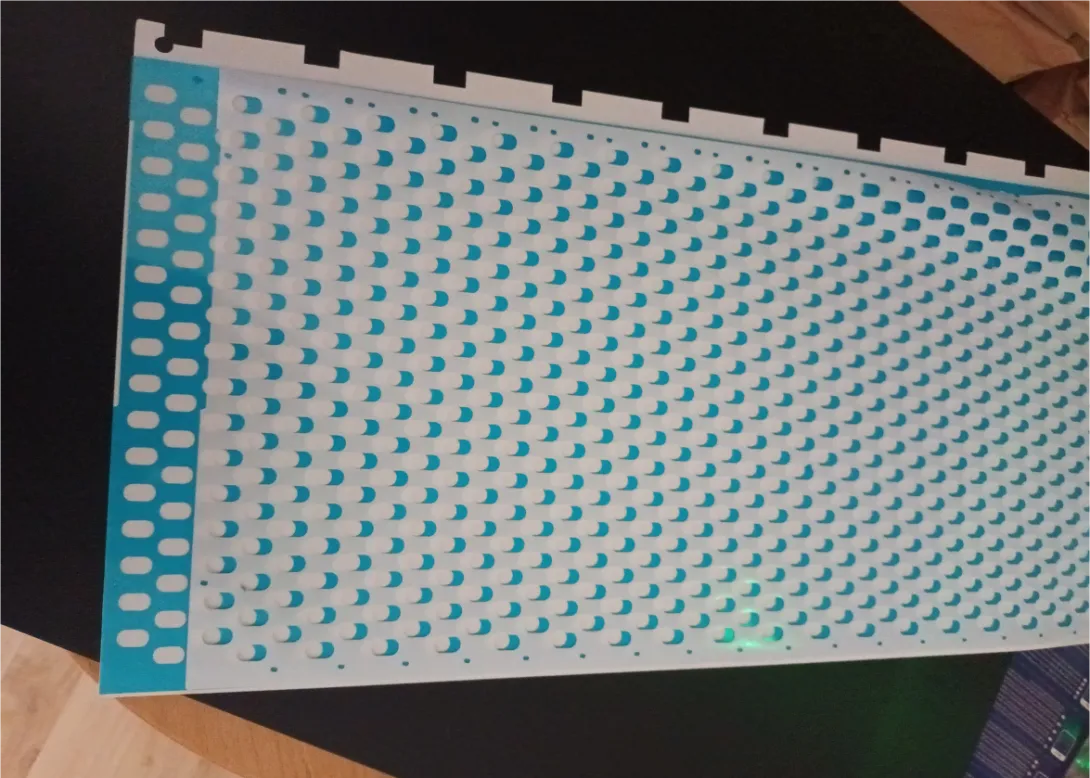

2️⃣ Insulation of Battery Modules and Packs

Cells are grouped into modules, then assembled into battery packs. These modules require reinforced insulation to:

✔ Limit electrical interference between cells.

✔ Prevent the spread of thermal runaway.

✔ Ensure the stability of the electrical field in the battery pack.

Polyester (PET) tapes to separate cells.

Fire-resistant polymer films conforming to safety standards.

Insulating and cushioning foams to reduce the impact of vibrations.

📌 Example: A UL94 V0 polymer film between modules prevents any electrical arcs and enhances the reliability of the battery pack.

3️⃣ Insulation of Bus Bars and Electrical Connections

Bus bars carry energy between modules and require effective insulation to:

✔ Reduce energy loss.

✔ Prevent uncontrolled electrical discharges.

✔ Improve the lifespan of electrical connections.

High-performance PET tapes ➝ Optimal protection of connections.

High-voltage polymer films ➝ Advanced dielectric insulation.

Solutions conforming to UL94 V0 and IEC 62619 standards.

📌 Example: An insulating PET tape applied on a bus bar limits electrical losses and ensures a more stable energy transmission.

What Materials for Which Battery?

🔎 Not sure which material to choose? Here is a quick guide based on the type of battery:

| Battery Type | Meilleures solutions d’isolation | Pourquoi ? | |

|---|---|---|---|

| Cylindrical EV Battery | Polyimide tapes + silicone foams | Enhanced thermal and electrical resistance |

| Pouch Cells EV Battery | UL94 V0 tapes + PET films | Weight reduction and safety improvement |

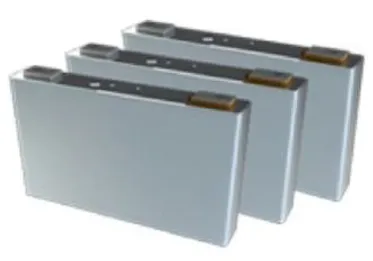

| Prismatic EV Battery | Fire-resistant tapes + cushioning foams | Increased stability and vibration reduction |

| Solid Electrolyte EV Battery | Polymer films + high-strength tapes | Better insulation and improved longevity |

Comparison of EV Battery Electrical Insulation Solutions

List not exhaustive, feel free to contact us.

| Reference | Type | Thickness | Main Application | Standard | |

|---|---|---|---|---|---|

| 5369 | Polyimide Tape | 30 µm | Electrode Insulation | UL94 V0 | Quote |

| 5357DG | Polyimide Tape | 57 µm | Electrolytic Sealing | UL94 V0 | Quote |

| 61395 | Polyimide Tape | 50 µm | Lithium-ion Cell Insulation | UL94 V0 | Quote |

| 58351 | Transparent PET Tape | 73 µm | Electrical Insulation with Anti-repulsion Property | - | Quote |

| 58352 | Blue PET Tape | 85 µm | Wrapping of Cells and Isolation of Metal Parts | - | Quote |

| 58353 | Black PET Tape | 85 µm | Battery Cell Wrapping and Electrical Insulation | FMVSS 302 | Quote |

| 58356 | Black PET Tape | 130 µm | Electrical Insulation of EV Components | - | Quote |

| 58337 | PET Tape | 75 µm | Electrical Insulation with Anti-repulsion Performance | - | Quote |

| 58347 | Blue PET Tape | 110 µm | Wrapping of Cells and Isolation of Metal Parts | - | Quote |

| 64250 | MOPP Adhesive Tape | 79 µm | Equipment Transport Security | - | Quote |

| 2205 | Polyimide Tape | 50 µm | Cathode and Anode Insulation | UL94 V0 | Quote |

| 911 | Acrylic Tape | 1.1 mm | Electrical and Thermal Insulation | UL94 V0 | Quote |

| 5413 | Kapton Polyimide Tape | 25 µm | Electrical and Thermal Insulation | UL94 V0 | Quote |

What is the Difference Between Polyimide Tape and Polyester (PET) Tape?

Polyimide tape provides high thermal and electrical resistance, making it ideal for insulating battery cells.

Polyester (PET) tape, on the other hand, is lighter and often used to insulate bus bars and electrical connections.

Why Choose Adezif?

We don't just sell materials. We provide solutions tailored to each project:

UL94 V0, IEC 62619, and ISO 16750 certified materials

Optimized electrical insulation for each type of battery

A wide range of adhesive tapes and insulating films

Personalized technical support for your specific needs

📞 Contact us and discuss with our technical experts!